- Home Page

- Company Profile

-

Our Products

- Oxidized Polyethylene Wax

- Pvc impact modifier

- MBS Impact Modifier

- pvc impact modifier

- PVC Impact Modifier

- Chlorinated Polyethylene

- Acrylic Impact Modifier

- ACM Impact Modifier

- CPE 135A

- ACM Impact Modifier

- Acrylic Impact Modifier

- MBS RESIN

- Acrylic Impact Modifier

- Chlorinated polyethylene

- ACM Impact Modifier

- PVC Impact Modifier

- OA- 123 Oxidized Polyethylene Wax

- Oxidized Polyethylene Wax module

- Oxidized polyethylene wax module

- Oxidized polyethylene wax module

- MBS Impact Modifier

- PVC Foaming Regulator

- Acrylic Processing Aid

- Acrylic Processing Aid

- High molecular weight processing aid

- PVC Foaming Regulator

- PVC Processing Aid

- Processing Aid ACR401

- Lubricant Processing Aid

- San Processing Aid

- Pvc Processing Aid

- Impact Modifier for PVC Pipe

- High Molecular Weight Processing Aid

- PVC Lubricating Processing Aids

- Acrylic Processing Aids

- SAN Processing Aid

- Acrylic Processing Aid

- Processing Aid

- Lubricant Processing Aid

- Acrylic Processing Aid

- Hydrotalcite

- ASA Resin

- Calcium stearate

- Chlorinated Polyethylene

- PVC Raw Material

- NC Blowing Agent

- Additives for PVC

- MBS Resin

- Antioxidant SBM

- MBS Impact Modifier

- PVC Additives

- CPE 135B

- PVC Compound Stabilizer

- Calcium Stearate

- Methyl tin stabilizer

- PVC Raw Material

- Additives for PVC

- PVC Stabilizer

- ASA Granule

- PVC Foaming Regulator

- Chlorinated Polyethylene

- Dike tone

- AC Blowing Agent

- Hydrotalcite HTC-3

- Low Density Oxidized Polyethylene

- High Density Oxidized Polyethylene

- PVC Foaming Agent

- PVC Heat Stabilizer

- Synthetic Hydrotalcite

- Chlorinated Polyethylene

- CPVC 1

- ASA Resin

- Ca Zn Stabilizer

- PVC Additives

- Wax

- Oxidized Pe Wax

- Oxidized Polythethylene Wax (OPE)

- High Density Oxidized Polyethylene

- Oxidized PE Wax

- Oxidized Polyethylene Wax

- Oxidized Polyethylene Wax

- PE WAX

- Low Density Oxidized Polyethylene

- PE Wax

- Fischer Tropsch Wax

- FT Wax

- Polypropylene Wax

- Oxidized polyethylene wax module

- Oxidized polyethylene wax module

- Chlorinated Polyethylene CPE135A

- PVC Stabilizer

- Oxidized Polyethylene Wax

- More Info

- Contact Us

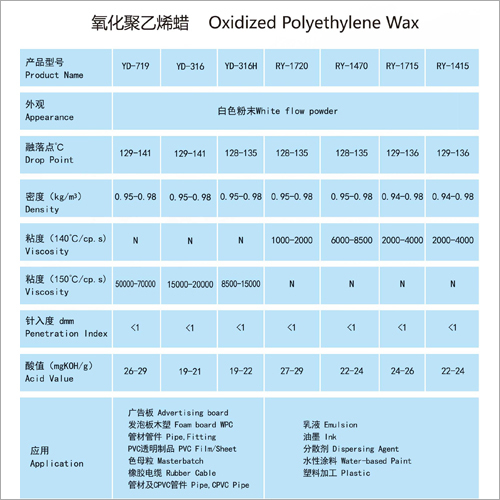

Oxidized Polyethylene Wax

Oxidized Polyethylene Wax Specification

- Chemical Name

- Chemical Auxiliary Agent

- Other Names

- Honeywell AC316A

- Classification

- Chemical Auxiliary Agent

- Color

- White

- Form

- Wax

- Application

- Used in many products, such as PVC compound, PVC profile, PVC pipe, PVC cable filler, TPE processing aids, hot melt adhesives, and PVC sheet.

Oxidized Polyethylene Wax Trade Information

- Minimum Order Quantity

- 1 Ton

- FOB Port

- Shandong, China

- Payment Terms

- Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- Supply Ability

- 300 Tons Per Day

- Delivery Time

- 12 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- acked in 25kg woven or kraft paper ba

- Main Export Market(s)

- Australia, South America, Middle East, Western Europe, Central America, Africa, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

About Oxidized Polyethylene Wax

High density Oxidized Polyethylene Wax OA916A oxidation is an oxidation polymer with great performance and used as a functional processing aid. Physicochemical Properties Index/Product Name OA916A Appearance White powder or granule Acid Number 15-18mg KOH/g Hardness@2577 F 0.5dmm Drop Point ,Mettler 140 Density 0.98g/cc Vicosity@150302F 9000cps Product Benefits and Application Used in many products, such as PVC compound, PVC profile, PVC pipe, PVC cable filler, TPE processing aids, hot melt adhesives, and PVC sheet. Material Safety Data Sheets MSDS provides information about the hazards and safe handling methods. Storage, Packing & Transportation OA916A is packed in 25kg woven or kraft paper bag. It is better to avoid isolation, drench. And, store this product in cool and draughty area. This product comes with a shelf life of one year. Countertypes Honeywell AC316AFAQs of Oxidized Polyethylene Wax:

Q: What is the classification of Oxidized Polyethylene Wax?

A: Oxidized Polyethylene Wax is classified as a Chemical Auxiliary Agent.Q: What is the color and form of Oxidized Polyethylene Wax?

A: The color of Oxidized Polyethylene Wax is white, and its form is wax.Q: What are other names for Oxidized Polyethylene Wax?

A: Oxidized Polyethylene Wax is also known as Honeywell AC316A.Q: What types of applications is Oxidized Polyethylene Wax used for?

A: Oxidized Polyethylene Wax is used in various applications, including PVC compound, PVC profile, PVC pipe, PVC cable filler, TPE processing aids, hot melt adhesives, and PVC sheets.Q: Is Oxidized Polyethylene Wax suitable for PVC-related products?

A: Yes, Oxidized Polyethylene Wax is suitable for numerous PVC-related products, such as PVC compound, profile, pipe, cable filler, and sheets.

- Minimum Order Quantity

- 1 Ton

- Supply Ability

- 300 Tons Per Day

- Delivery Time

- 12 Days

- Main Domestic Market

- All India

- Main Export Market(s)

- Australia, South America, Middle East, Western Europe, Central America, Africa, Asia, Eastern Europe, North America

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Wax Category

Oxidized Polyethylene Wax

Price Range 1150.00 - 1650.00 USD ($) / Ton

Minimum Order Quantity : 10 Tons,

Form : Wax

Color : White

Application : Coating Auxiliary Agents, Leather Auxiliary Agents, Plastic Au

CAS No : 9002884

Oxidized Pe Wax

Price Range 25.00 - 65.00 USD ($) / Kilograms

Minimum Order Quantity : 10000 Kilograms

Form : Wax

Color : White

Application : Coating Auxiliary Agents, Electronics Chemicals, Leather Auxiliary Agents, Paper Chemicals, Petroleum Additives, Plastic Auxiliary Agents, Rubber Auxiliary Agents, Surfactants, Textile Auxiliary Agents

CAS No : 9002884

Oxidized Polythethylene Wax (OPE)

Price Range 1180.00 - 1350.00 USD ($) / Ton

Minimum Order Quantity : 10 Tons

Form : Wax

Color : White

CAS No : 9002884

Fischer Tropsch Wax

Form : Solid

Color : White

Application : Road construction adhesives coatings

CAS No : 68855101

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese