- Home Page

- Company Profile

-

Our Products

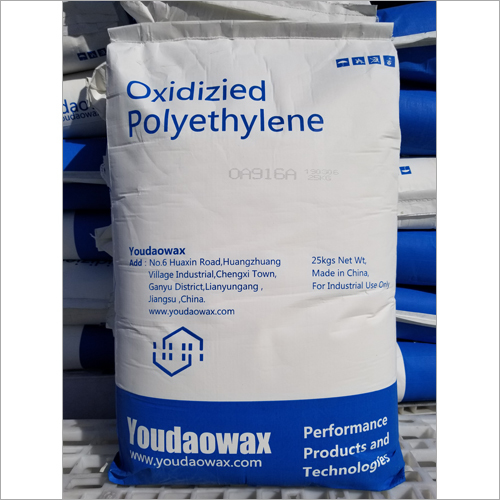

- Oxidized Polyethylene Wax

- Pvc impact modifier

- MBS Impact Modifier

- pvc impact modifier

- PVC Impact Modifier

- Chlorinated Polyethylene

- Acrylic Impact Modifier

- ACM Impact Modifier

- CPE 135A

- ACM Impact Modifier

- Acrylic Impact Modifier

- MBS RESIN

- Acrylic Impact Modifier

- Chlorinated polyethylene

- ACM Impact Modifier

- PVC Impact Modifier

- OA- 123 Oxidized Polyethylene Wax

- Oxidized Polyethylene Wax module

- Oxidized polyethylene wax module

- Oxidized polyethylene wax module

- Lubricant Processing Aid

- MBS Impact Modifier

- PVC Foaming Regulator

- Acrylic Processing Aid

- Acrylic Processing Aid

- High molecular weight processing aid

- PVC Foaming Regulator

- PVC Processing Aid

- Processing Aid ACR401

- Lubricant Processing Aid

- San Processing Aid

- Pvc Processing Aid

- Impact Modifier for PVC Pipe

- High Molecular Weight Processing Aid

- PVC Lubricating Processing Aids

- Acrylic Processing Aids

- SAN Processing Aid

- Acrylic Processing Aid

- Processing Aid

- Lubricant Processing Aid

- Acrylic Impact Modifier AIM60

- Acrylic Impact Modifier AIM-60

- MBS IMPACT MODIFIER B-126

- Acrylic Processing Aid

- PVC External Lubricant

- PVC Internal Lubricant

- PVC Internal Lubricant

- PVC Lubricants

- External PVC lubricants

- Oxidized Polyethylene wax

- Lubricants for PVC

- PVC Internal Lubricant

- Lubricant for PVC

- PVC External Lubricant

- PVC Lubricants Flaxes

- Lubricant Processing Aid

- PVC LUBRICANT PROCESSING AID P-175

- Acrylic processing aid module

- Pvc Processing Aid Acr-401

- Hydrotalcite

- ASA Resin

- Calcium stearate

- PVC Raw Material

- Chlorinated Polyethylene

- NC Blowing Agent

- Additives for PVC

- MBS Resin

- Antioxidant SBM

- MBS Impact Modifier

- PVC Additives

- CPE 135B

- Calcium Stearate

- PVC Compound Stabilizer

- Additives for PVC

- Methyl tin stabilizer

- PVC Raw Material

- PVC Foaming Regulator

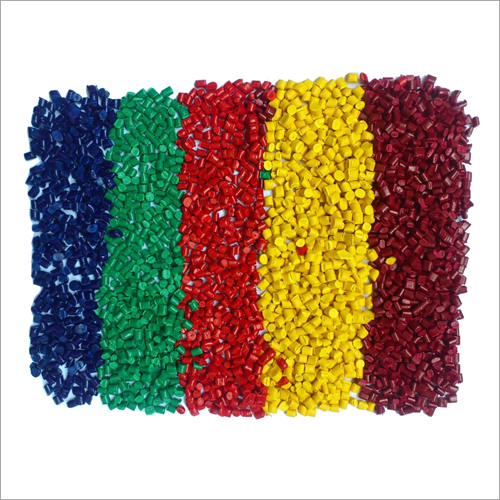

- ASA Granule

- PVC Stabilizer

- Chlorinated Polyethylene

- Dike tone

- AC Blowing Agent

- Hydrotalcite HTC-3

- Low Density Oxidized Polyethylene

- High Density Oxidized Polyethylene

- PVC Foaming Agent

- PVC Heat Stabilizer

- Synthetic Hydrotalcite

- Chlorinated Polyethylene

- CPVC 1

- ASA Resin

- Ca Zn Stabilizer

- PVC Additives

- Wax

- Oxidized Pe Wax

- Oxidized Polythethylene Wax (OPE)

- High Density Oxidized Polyethylene

- Oxidized PE Wax

- Oxidized Polyethylene Wax

- Oxidized Polyethylene Wax

- PE WAX

- Low Density Oxidized Polyethylene

- PE Wax

- Fischer Tropsch Wax

- FT Wax

- Polypropylene Wax

- Oxidized polyethylene wax module

- Oxidized polyethylene wax module

- Chlorinated Polyethylene CPE135A

- PVC Stabilizer

- PVC Impact Modifier Module

- Oxidized Polyethylene Wax

- More Info

- Contact Us

ASA Granule

ASA Granule Specification

- Shape

- Cylindrical / Spherical

- Taste

- Odorless

- Structural Formula

- N/A (Copolymer)

- Shelf Life

- 1224 Months

- Physical Form

- Granules

- Application

- Automotive Exterior Parts, Outdoor Furniture, Building Profiles, Electronic Housings

- Solubility

- Insoluble in Water, Soluble in Organic Solvents

- Molecular Formula

- (C8H7NO)n-(C8H8)n-(C5H8O2)n

- Grade

- Injection Molding Grade / Extrusion Grade

- Particle Size

- 25 mm (Granule size)

- Ph Level

- Neutral (pH 7)

- Smell

- No Significant Odor

- Molecular Weight

- Variable (Polymeric Material)

- Melting Point

- 210230C

- Other Names

- ASA Resin, Acrylonitrile Styrene Acrylate Polymer

- Density

- 1.10 Gram per cubic centimeter(g/cm3)

- Boiling point

- Not Applicable (Polymer)

- Poisonous

- Non-Poisonous

- Chemical Name

- Acrylonitrile Styrene Acrylate (ASA) Granule

- CAS No

- 26271-64-3

- Type

- Thermoplastic Resin

- Color

- White, Off-white, or Customized

- EINECS No

- 247-557-0

- Usage

- Injection Molding, Extrusion, Automotive Parts, Construction Materials, Consumer Products

- Purity(%)

- >99%

- Storage

- Cool, Dry Place; Avoid Direct Sunlight

- Appearance

- Opaque Granules

About ASA Granule

Physicochemical Properties

| Item | Test Method | Data | Unit |

| Melt Flow Rate | ASTM D-1238 | 14.6 | g/10min |

| Water Absorption | ASTM D-570 | 0.3 | % |

| specific gravity | ASTM D-792 | 1.08 |

|

| Shrink rate | ASTM D-955 | 0.002-0.004 | % |

| Flexural Strength | ASTM D-790 | 1120 | kg/cm |

| Rockwell hardness | ASTM D-785 | 98 | M scale |

| Strength of extension | ASTM D-638 | 660 | kg/cm |

| Flexural modulus | ASTM D-790 | 7 | % |

| Tensile Strength | ASTM D-638 | 46 | kg/cm |

| The IZOD notched impact strength | ASTM D-256 | 19 | Kj/m2 |

| Vicat Softening Point | ASTM D-1525 | 97 | |

| Heat Deflection Temp | ASTM-D-648 | 83 | |

| Combustibility | UL 94 | HB | CLASS |

Exceptional Durability and Versatility

ASA Granule demonstrates superior resistance to UV rays and outdoor weather, ensuring longevity for products exposed to harsh environments. Its robust impact strength and moderate shrinkage rate contribute to reliable accuracy during molding, making it a preferred choice for manufacturers in automotive, construction, and consumer goods sectors.

Safe and Environmentally Responsible

ASA Granule exhibits self-extinguishing flammability and complies with RoHS standards, supporting safe usage in electrical and electronic components. Its excellent recyclability and non-poisonous nature make it an environmentally friendly option for responsible manufacturers, distributors, and exporters across various industries.

FAQs of ASA Granule:

Q: How is ASA Granule typically processed in manufacturing?

A: ASA Granule is best processed using injection molding or extrusion methods at temperatures between 230260C. These techniques help create durable automotive parts, building profiles, and consumer products with precise dimensions and excellent surface finish.Q: What are the main benefits of choosing ASA Granule for outdoor applications?

A: The granules superior weatherability and excellent UV resistance ensure minimal degradation and color fading in outdoor environments. Its high impact strength adds extra durability, making it ideal for outdoor furniture, building profiles, and automotive exterior parts.Q: Where is ASA Granule predominantly used?

A: ASA Granule finds widespread use in the automotive industry for exterior components, in construction for window profiles and building materials, as well as in consumer products like outdoor furniture, and electronic housings due to its resilience and aesthetic versatility.Q: What safety features does ASA Granule offer in finished products?

A: ASA Granule has a self-extinguishing property and complies with RoHS standards, making it suitable for applications requiring fire safety and environmental compliance, such as electrical housings and consumer electronics.Q: When should ASA Granule be chosen over other polymer resins?

A: ASA Granule is preferred when high impact strength, resistance to UV and weather, and excellent thermal stability are needed, especially for products exposed to outdoor conditions or stringent safety requirements.Q: How should ASA Granule be stored to maintain its quality?

A: It should be stored in a cool, dry place, away from direct sunlight, to preserve its purity and physical integrity over its shelf life of 1224 months.Q: What is the recyclability status of ASA Granule and its impact on sustainability?

A: ASA Granule is recyclable, facilitating sustainable manufacturing practices and contributing to reduced environmental impact for manufacturers and consumers seeking environmentally responsible solutions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hydrotalcite Category

PVC Stabilizer

Price Range 1150.00 - 1650.00 USD ($) / Ton

Minimum Order Quantity : 10 Tons

Grade : Industrial Grade

Purity(%) : 98.5%

Smell : Stimulus

Appearance : Clear Powder

PVC Heat Stabilizer

Price Range 1150.00 - 1650.00 USD ($) / Ton

Minimum Order Quantity : 10 Tons

Grade : Industrial Grade

Purity(%) : 99.5%

Smell : Stimulus

Appearance : Other

ASA Resin

Grade : Industrial Grade

Purity(%) : 99%

Smell : Other, Odorless

Appearance : Other, Granules

High Density Oxidized Polyethylene

Price Range 1150.00 - 1650.00 USD ($) / Ton

Minimum Order Quantity : 10 Tons

Grade : Industrial Grade

Purity(%) : 99%

Smell : Stimulus

Appearance : Clear Powder

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese