- Home Page

- Company Profile

-

Our Products

- Oxidized Polyethylene Wax

- Pvc impact modifier

- MBS Impact Modifier

- pvc impact modifier

- PVC Impact Modifier

- Chlorinated Polyethylene

- Acrylic Impact Modifier

- ACM Impact Modifier

- CPE 135A

- ACM Impact Modifier

- Acrylic Impact Modifier

- MBS RESIN

- Acrylic Impact Modifier

- Chlorinated polyethylene

- ACM Impact Modifier

- PVC Impact Modifier

- OA- 123 Oxidized Polyethylene Wax

- Oxidized Polyethylene Wax module

- Oxidized polyethylene wax module

- Oxidized polyethylene wax module

- Lubricant Processing Aid

- MBS Impact Modifier

- PVC Foaming Regulator

- Acrylic Processing Aid

- Acrylic Processing Aid

- High molecular weight processing aid

- PVC Foaming Regulator

- PVC Processing Aid

- Processing Aid ACR401

- Lubricant Processing Aid

- San Processing Aid

- Pvc Processing Aid

- Impact Modifier for PVC Pipe

- High Molecular Weight Processing Aid

- PVC Lubricating Processing Aids

- Acrylic Processing Aids

- SAN Processing Aid

- Acrylic Processing Aid

- Processing Aid

- Lubricant Processing Aid

- Acrylic Impact Modifier AIM60

- Acrylic Impact Modifier AIM-60

- MBS IMPACT MODIFIER B-126

- Acrylic Processing Aid

- PVC External Lubricant

- PVC Internal Lubricant

- PVC Internal Lubricant

- PVC Lubricants

- External PVC lubricants

- Oxidized Polyethylene wax

- Lubricants for PVC

- PVC Internal Lubricant

- Lubricant for PVC

- PVC External Lubricant

- PVC Lubricants Flaxes

- Lubricant Processing Aid

- PVC LUBRICANT PROCESSING AID P-175

- Acrylic processing aid module

- Pvc Processing Aid Acr-401

- Hydrotalcite

- Calcium stearate

- ASA Resin

- Chlorinated Polyethylene

- PVC Raw Material

- NC Blowing Agent

- Additives for PVC

- MBS Impact Modifier

- Antioxidant SBM

- MBS Resin

- PVC Additives

- CPE 135B

- PVC Compound Stabilizer

- Calcium Stearate

- Additives for PVC

- Methyl tin stabilizer

- PVC Raw Material

- PVC Foaming Regulator

- ASA Granule

- PVC Stabilizer

- Dike tone

- Chlorinated Polyethylene

- AC Blowing Agent

- Hydrotalcite HTC-3

- Low Density Oxidized Polyethylene

- High Density Oxidized Polyethylene

- PVC Foaming Agent

- PVC Heat Stabilizer

- Synthetic Hydrotalcite

- Chlorinated Polyethylene

- CPVC 1

- ASA Resin

- Ca Zn Stabilizer

- PVC Additives

- Wax

- Oxidized Pe Wax

- Oxidized Polythethylene Wax (OPE)

- High Density Oxidized Polyethylene

- Oxidized PE Wax

- Oxidized Polyethylene Wax

- Oxidized Polyethylene Wax

- PE WAX

- Low Density Oxidized Polyethylene

- PE Wax

- Fischer Tropsch Wax

- FT Wax

- Polypropylene Wax

- Oxidized polyethylene wax module

- Oxidized polyethylene wax module

- Chlorinated Polyethylene CPE135A

- PVC Stabilizer

- PVC Impact Modifier Module

- Oxidized Polyethylene Wax

- More Info

- Contact Us

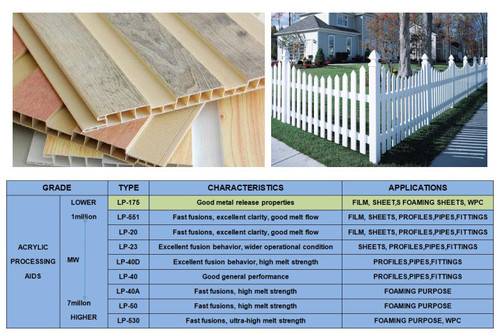

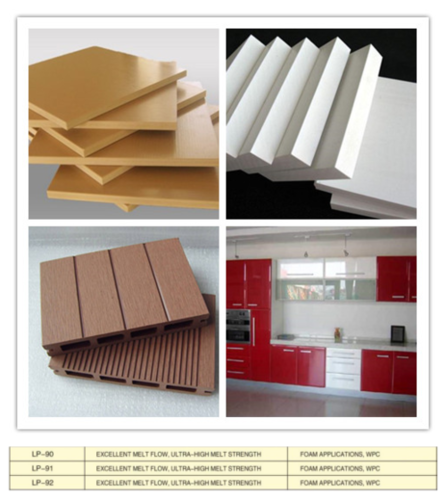

Acrylic Processing Aid

Acrylic Processing Aid Specification

- Particle Size

- 40 - 100 mesh

- Molecular Formula

- (C5O2H8.C2H4)n

- Poisonous

- Non-poisonous

- Shelf Life

- 24 months

- Physical Form

- Powder

- Solubility

- Insoluble in water

- Density

- 0.55 Gram per cubic centimeter(g/cm3)

- Structural Formula

- --

- Shape

- Powdered

- Grade

- Industrial Grade

- Other Names

- Acrylic Impact Modifier, APA

- Smell

- Odorless

- Melting Point

- >300C (decomposes)

- Ph Level

- Neutral

- Molecular Weight

- Varies (Polymer)

- Taste

- Odorless

- Application

- Used to improve processability and surface quality in PVC and related plastic industries

- Chemical Name

- Acrylic Processing Aid

- CAS No

- 25777-71-3

- Type

- Processing Aid

- Color

- White

- EINECS No

- 607-487-2

- Usage

- Plastic Auxiliary Agents, specifically for PVC

- Purity(%)

- >99%

- Storage

- Store in a cool, dry, and ventilated place

- Appearance

- Free-flowing white powder

- Brand Name

- Various / Customizable

- Main Function

- Improves fusion, melt strength, and gloss in PVC products

- FDA Approved

- No

- Storage Temperature

- Below 30C

- Moisture content

- 0.5%

- Ash Content

- 1.0%

- Bulk Density

- 0.45 0.05 g/cm

- Environmental Impact

- Non-hazardous, does not contain heavy metals or solvents

- Thermal Stability

- Excellent

- Compatibility

- Highly compatible with PVC

- Packaging Type

- 25kg bags, or per customer requirement

- Refractive Index

- 1.49 - 1.53

- Vicat Softening Point

- >80C

- Recommended Dosage

- 2.0 - 8.0 phr depending on application

About Acrylic Processing Aid

Unlock unrivaled performance in PVC products with Various / Customizable Acrylic Processing Aida monumental solution designed for top-drawer results. This personalized aid is a bargain for manufacturers seeking improved fusion, exceptional melt strength, and a radiant gloss. Redeem superior compatibility and seamless processing in PVC applications with this industrial-grade, odorless powder. Packaged in 25kg bags or tailored to your requirements, it boasts low moisture content (0.5%) and formidable thermal stability. With over 99% purity, non-hazardous nature, and white, free-flowing appearance, this aid stands out as a safe, dependable, and high-efficiency choice.

Expansive Applications and Key Features of Acrylic Processing Aid

Acrylic Processing Aid shines in multiple PVC industries, boosting processability, gloss, and melt strength, while enhancing fusion. Its use is mainstay in manufacturing PVC pipes, cables, profiles, sheets, and films, among other plastic-based products. Highly compatible and non-poisonous, this powdery modifier is easy to integrate, offering monumental environmental safety and performance. Its fine particle size (40100 mesh) and stable physical characteristics make it indispensable wherever enhanced production quality and surface finish are critical.

Domestic Market, Outlay, and Tailored Packaging Solutions

Our Acrylic Processing Aid leads the domestic market, distributed widely to manufacturers, exporters, and suppliers across China. Payment terms are flexible, accommodating various client preferences to simplify your outlay. Packaging is top-drawerstandard 25kg bags or customized per customer needsensuring your product is dispatched securely and promptly. The dispatching process is streamlined to facilitate efficient order fulfillment and maintain product quality during delivery, safeguarding your investment every step of the way.

Expansive Applications and Key Features of Acrylic Processing Aid

Acrylic Processing Aid shines in multiple PVC industries, boosting processability, gloss, and melt strength, while enhancing fusion. Its use is mainstay in manufacturing PVC pipes, cables, profiles, sheets, and films, among other plastic-based products. Highly compatible and non-poisonous, this powdery modifier is easy to integrate, offering monumental environmental safety and performance. Its fine particle size (40100 mesh) and stable physical characteristics make it indispensable wherever enhanced production quality and surface finish are critical.

Domestic Market, Outlay, and Tailored Packaging Solutions

Our Acrylic Processing Aid leads the domestic market, distributed widely to manufacturers, exporters, and suppliers across China. Payment terms are flexible, accommodating various client preferences to simplify your outlay. Packaging is top-drawerstandard 25kg bags or customized per customer needsensuring your product is dispatched securely and promptly. The dispatching process is streamlined to facilitate efficient order fulfillment and maintain product quality during delivery, safeguarding your investment every step of the way.

FAQs of Acrylic Processing Aid:

Q: How do I effectively use Acrylic Processing Aid in PVC manufacturing?

A: To maximize results, introduce 2.08.0 phr of the aid directly into the PVC formulation based on your process requirements. Adjust the dosage accordingly for optimal fusion, melt strength, and gloss.Q: What are the key benefits of incorporating this processing aid into my products?

A: The main benefits include easier PVC processing, superior surface quality, enhanced gloss, increased melt strength, and improved fusion, all contributing to top-drawer product performance.Q: When should Acrylic Processing Aid be added during the manufacturing process?

A: For best results, add the processing aid at the mixing stage alongside other additives and PVC resins, allowing full integration before melt processing.Q: Where is this product commonly applied?

A: This processing aid is ideal for use in PVC pipes, cables, profiles, sheets, films, and various other extruded or molded plastic products across diverse industries.Q: What makes this aid environmentally safe?

A: It is non-hazardous, free from heavy metals and solvents, and poses no poison risk, making it both safe for workers and environmentally friendly.Q: How should the Acrylic Processing Aid be stored before use?

A: Keep the product in a cool, dry, and ventilated area, away from direct sunlight and below 30C, to maintain its optimal properties throughout its 24-month shelf life.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in MBS Impact Modifier Category

Impact Modifier for PVC Pipe

Price Range 350.00 - 1100.00 USD ($) / Ton

Minimum Order Quantity : 5 Tons

Physical Form : Powder

Type : Chemical Additive

Color : White

Shape : Granules

Acrylic Processing Aid

Price Range 1350.00 - 1550.00 USD ($) / Ton

Minimum Order Quantity : 5 Tons

Physical Form : Powder

Type : Chemical Additive

Color : White

Shape : Granules

PVC Foaming Regulator

Price Range 850.00 - 1250.00 USD ($) / Ton

Minimum Order Quantity : 5 Tons

Physical Form : Powder

Type : Chemical Additive

Color : White

Shape : Granules

San Processing Aid

Price Range 1280.00 - 1550.00 USD ($) / Ton

Minimum Order Quantity : 5 Tons

Physical Form : Powder

Type : Chemical Additive Agent

Color : White

Shape : Granules

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese