- Home Page

- Company Profile

-

Our Products

- Oxidized Polyethylene Wax

- Pvc impact modifier

- MBS Impact Modifier

- pvc impact modifier

- PVC Impact Modifier

- Chlorinated Polyethylene

- Acrylic Impact Modifier

- ACM Impact Modifier

- CPE 135A

- ACM Impact Modifier

- Acrylic Impact Modifier

- MBS RESIN

- Acrylic Impact Modifier

- Chlorinated polyethylene

- ACM Impact Modifier

- PVC Impact Modifier

- OA- 123 Oxidized Polyethylene Wax

- Oxidized Polyethylene Wax module

- Oxidized polyethylene wax module

- Oxidized polyethylene wax module

- Lubricant Processing Aid

- MBS Impact Modifier

- PVC Foaming Regulator

- Acrylic Processing Aid

- Acrylic Processing Aid

- High molecular weight processing aid

- PVC Foaming Regulator

- PVC Processing Aid

- Processing Aid ACR401

- Lubricant Processing Aid

- San Processing Aid

- Pvc Processing Aid

- Impact Modifier for PVC Pipe

- High Molecular Weight Processing Aid

- PVC Lubricating Processing Aids

- Acrylic Processing Aids

- SAN Processing Aid

- Acrylic Processing Aid

- Processing Aid

- Lubricant Processing Aid

- Acrylic Impact Modifier AIM60

- Acrylic Impact Modifier AIM-60

- MBS IMPACT MODIFIER B-126

- Acrylic Processing Aid

- PVC External Lubricant

- PVC Internal Lubricant

- PVC Internal Lubricant

- PVC Lubricants

- External PVC lubricants

- Oxidized Polyethylene wax

- Lubricants for PVC

- PVC Internal Lubricant

- Lubricant for PVC

- PVC External Lubricant

- PVC Lubricants Flaxes

- Lubricant Processing Aid

- PVC LUBRICANT PROCESSING AID P-175

- Acrylic processing aid module

- Pvc Processing Aid Acr-401

- Hydrotalcite

- Calcium stearate

- ASA Resin

- Chlorinated Polyethylene

- PVC Raw Material

- NC Blowing Agent

- Additives for PVC

- MBS Impact Modifier

- Antioxidant SBM

- MBS Resin

- PVC Additives

- CPE 135B

- PVC Compound Stabilizer

- Calcium Stearate

- Additives for PVC

- Methyl tin stabilizer

- PVC Raw Material

- PVC Foaming Regulator

- ASA Granule

- PVC Stabilizer

- Dike tone

- Chlorinated Polyethylene

- AC Blowing Agent

- Hydrotalcite HTC-3

- Low Density Oxidized Polyethylene

- High Density Oxidized Polyethylene

- PVC Foaming Agent

- PVC Heat Stabilizer

- Synthetic Hydrotalcite

- Chlorinated Polyethylene

- CPVC 1

- ASA Resin

- Ca Zn Stabilizer

- PVC Additives

- Wax

- Oxidized Pe Wax

- Oxidized Polythethylene Wax (OPE)

- High Density Oxidized Polyethylene

- Oxidized PE Wax

- Oxidized Polyethylene Wax

- Oxidized Polyethylene Wax

- PE WAX

- Low Density Oxidized Polyethylene

- PE Wax

- Fischer Tropsch Wax

- FT Wax

- Polypropylene Wax

- Oxidized polyethylene wax module

- Oxidized polyethylene wax module

- Chlorinated Polyethylene CPE135A

- PVC Stabilizer

- PVC Impact Modifier Module

- Oxidized Polyethylene Wax

- More Info

- Contact Us

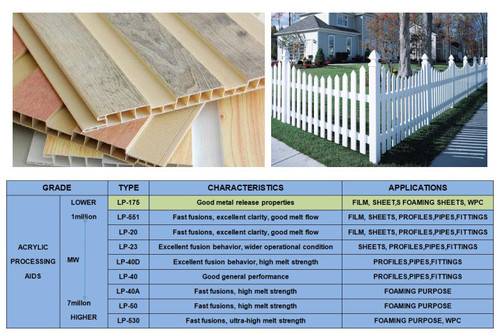

Acrylic Processing Aid

Acrylic Processing Aid Specification

- Smell

- Stimulus

- Application

- Plastic, Textile Industry

- Shelf Life

- 1 Years

- Shape

- Granules

- Grade

- Industrial Grade

- Physical Form

- Powder

- CAS No

- Compound

- Type

- Chemical Additive

- Color

- White

- Usage

- Plastic Auxiliary Agents

- Purity(%)

- 100%

- Storage

- Room Temperature

- Appearance

- Crystal Powder

Acrylic Processing Aid Trade Information

- Minimum Order Quantity

- 5 Tons

- FOB Port

- Shandong, China

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Cash Advance (CA)

- Supply Ability

- 10000 Tons Per Month

- Delivery Time

- 7-12 Days

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- 20kg per bag or by request of clients.

- Main Export Market(s)

- Western Europe, Asia, Australia, North America, Eastern Europe, Middle East, Africa, Central America, South America

- Main Domestic Market

- All India

About Acrylic Processing Aid

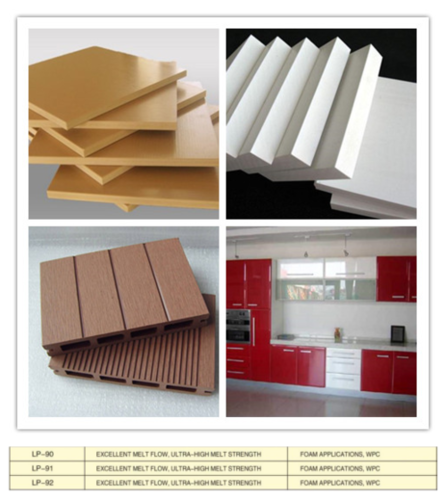

Acrylic Processing Aid referred to as ACR processing aid ,it is an acrylic ester copolymer, which belongs to core-shell structure. Compared with PVC, its molecular weight is higher, generally about 1-8 million (weight average molecular weight), and its true density is 1.05 g / cm3-1.20 g / cm3. It is made of various kinds of acrylic acid and crosslinking agent, emulsifier, initiator, molecular weight regulator and other raw materials, and after many times emulsion polymerization, the white micro non-toxic and non corrosive powder is prepared.Promotes faster fusion, increases melt strength,enhances extensibilityand improves melt homogeneity.Increases the surface quality of PVC products. Offering excellent wall-thickness controland good thermoforming capabilities.Accelerate fusion rate, increase productivity and decrease processing temperature.Better dispersion of additives into PVC, more homogenous melt of PVC, etc.Excellent clarity and surface quality for end-use products, superior fusion promotion for rigid and soft PVC. Increased output rates and improved production efficiency.Our processing aids equivalent to the Dow Paraloid K series,Kane Ace PA series,LG PA series,Mitsubishi Metablen P series,Arkema PLASTISTRENGTH P series,AKDENZ PRO,Shandong Rike HL series.LP-175 equivalent to Dow K-175,Kaneka PA-101,Arkema P-770.LP-551 equivalent to Arkema P-551,LG PA910,Baerlocher 3FK.LP-20 equivalent to Dow K-120ND,Kaneka PA20/PA210,LG PA821.LP-23 equivalent to Dow K-125,Kaneka PA-21/PA-310,LG PA-828,Baerlocher 10F.LP40D equivalent to Dow K-128,Arkema P-533.LP-40A equivalent to Dow K-400,LG PA930,Baerlocher 20F.LP-50 equivalent to Arkema P-531.LP-530 equivalent to Dow K435,Kaneka PA-60/PA-610.For TDS and MSDS, you can contact our Sales and Marketing Department or you can reach us through thecontact pageFAQs of Acrylic Processing Aid:

Q: What is the physical form of Acrylic Processing Aid?

A: The physical form of Acrylic Processing Aid is powder.Q: What is the purity percentage of Acrylic Processing Aid?

A: The purity percentage of Acrylic Processing Aid is 100%.Q: What industries can benefit from using Acrylic Processing Aid?

A: Acrylic Processing Aid is applicable in the plastic and textile industries.Q: How should Acrylic Processing Aid be stored?

A: Acrylic Processing Aid should be stored at room temperature.Q: What is the shelf life of Acrylic Processing Aid?

A: The shelf life of Acrylic Processing Aid is 1 year.

- Minimum Order Quantity

- 5 Tons

- Supply Ability

- 10000 Tons Per Month

- Delivery Time

- 7-12 Days

- Main Domestic Market

- All India

- Main Export Market(s)

- Western Europe, Asia, Australia, North America, Eastern Europe, Middle East, Africa, Central America, South America

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in MBS Impact Modifier Category

Acrylic Processing Aid

Application : Other, Used to improve processability and surface quality in PVC and related plastic industries

Type : Other, Processing Aid

Storage : Other, Store in a cool, dry, and ventilated place

Shelf Life : 24 months

PVC Foaming Regulator

Price Range 850.00 - 1250.00 USD ($) / Ton

Minimum Order Quantity : 5 Tons

Application : Industrial, Plastic

Type : Chemical Additive

Storage : Room Temperature

Shelf Life : 1 Years

PVC Processing Aid

Price Range 1125.00 - 1550.00 USD ($) / Ton

Minimum Order Quantity : 5 Tons

Application : Industrial, Plastic

Type : Chemical Additive

Storage : Room Temperature

Shelf Life : 1 Years

Processing Aid

Price Range 1180.00 - 1650.00 USD ($) / Ton

Minimum Order Quantity : 10 Tons

Application : Industrial, Plastic

Type : processing aid, Other

Storage : Room Temperature

Shelf Life : 2 Years

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese