- Home Page

- Company Profile

-

Our Products

- Oxidized Polyethylene Wax

- Pvc impact modifier

- MBS Impact Modifier

- pvc impact modifier

- PVC Impact Modifier

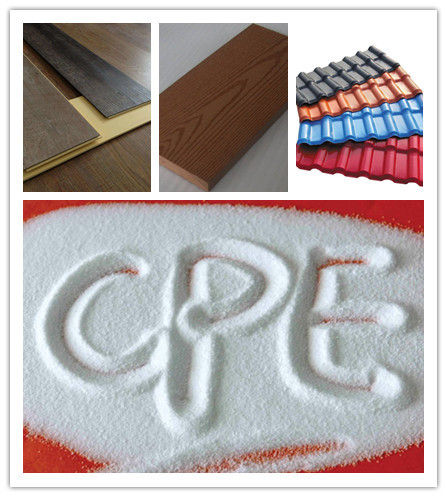

- Chlorinated Polyethylene

- Acrylic Impact Modifier

- ACM Impact Modifier

- CPE 135A

- ACM Impact Modifier

- Acrylic Impact Modifier

- MBS RESIN

- Acrylic Impact Modifier

- Chlorinated polyethylene

- ACM Impact Modifier

- PVC Impact Modifier

- OA- 123 Oxidized Polyethylene Wax

- Oxidized Polyethylene Wax module

- Oxidized polyethylene wax module

- Oxidized polyethylene wax module

- Lubricant Processing Aid

- MBS Impact Modifier

- PVC Foaming Regulator

- Acrylic Processing Aid

- Acrylic Processing Aid

- High molecular weight processing aid

- PVC Foaming Regulator

- PVC Processing Aid

- Processing Aid ACR401

- Lubricant Processing Aid

- San Processing Aid

- Pvc Processing Aid

- Impact Modifier for PVC Pipe

- High Molecular Weight Processing Aid

- PVC Lubricating Processing Aids

- Acrylic Processing Aids

- SAN Processing Aid

- Acrylic Processing Aid

- Processing Aid

- Lubricant Processing Aid

- Acrylic Impact Modifier AIM60

- Acrylic Impact Modifier AIM-60

- MBS IMPACT MODIFIER B-126

- Acrylic Processing Aid

- PVC External Lubricant

- PVC Internal Lubricant

- PVC Internal Lubricant

- PVC Lubricants

- External PVC lubricants

- Oxidized Polyethylene wax

- Lubricants for PVC

- PVC Internal Lubricant

- Lubricant for PVC

- PVC External Lubricant

- PVC Lubricants Flaxes

- Lubricant Processing Aid

- PVC LUBRICANT PROCESSING AID P-175

- Acrylic processing aid module

- Pvc Processing Aid Acr-401

- Hydrotalcite

- Calcium stearate

- ASA Resin

- Chlorinated Polyethylene

- PVC Raw Material

- NC Blowing Agent

- Additives for PVC

- MBS Impact Modifier

- Antioxidant SBM

- MBS Resin

- PVC Additives

- CPE 135B

- PVC Compound Stabilizer

- Calcium Stearate

- Additives for PVC

- Methyl tin stabilizer

- PVC Raw Material

- PVC Foaming Regulator

- ASA Granule

- PVC Stabilizer

- Dike tone

- Chlorinated Polyethylene

- AC Blowing Agent

- Hydrotalcite HTC-3

- Low Density Oxidized Polyethylene

- High Density Oxidized Polyethylene

- PVC Foaming Agent

- PVC Heat Stabilizer

- Synthetic Hydrotalcite

- Chlorinated Polyethylene

- CPVC 1

- ASA Resin

- Ca Zn Stabilizer

- PVC Additives

- Wax

- Oxidized Pe Wax

- Oxidized Polythethylene Wax (OPE)

- High Density Oxidized Polyethylene

- Oxidized PE Wax

- Oxidized Polyethylene Wax

- Oxidized Polyethylene Wax

- PE WAX

- Low Density Oxidized Polyethylene

- PE Wax

- Fischer Tropsch Wax

- FT Wax

- Polypropylene Wax

- Oxidized polyethylene wax module

- Oxidized polyethylene wax module

- Chlorinated Polyethylene CPE135A

- PVC Stabilizer

- PVC Impact Modifier Module

- Oxidized Polyethylene Wax

- More Info

- Contact Us

Acrylic Impact Modifier

MOQ : 5 Tons

Acrylic Impact Modifier Specification

- Smell

- Stimulus

- Grade

- Industrial Grade

- Shape

- Granules

- Shelf Life

- 2 Years

- Application

- Industrial, Textile Industry

- Physical Form

- Powder

- CAS No

- 25852-37-3

- Type

- Chemical Additive Agent

- Usage

- Construction Chemical Additive

- Purity(%)

- 99.9%

- Storage

- Room Temperature

- Appearance

- Clear Powder

Acrylic Impact Modifier Trade Information

- Minimum Order Quantity

- 5 Tons

- FOB Port

- Shandong, China

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Cash Advance (CA)

- Supply Ability

- 10000 Tons Per Month

- Delivery Time

- 7-12 Days

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- 25kg/bag,or as requirement.

- Main Export Market(s)

- Western Europe, Asia, Australia, North America, South America, Eastern Europe, Middle East, Central America

- Main Domestic Market

- All India

About Acrylic Impact Modifier

Acrylic impact modifier or namedACR impact modifier contains the core formed by acrylate crosslinked elastomer, and the shell composed of methyl methacrylate ethyl acrylate copolymer is outside the core. The impact strength of a good blend system of ACR and PVC can be more than 10 times higher than that of PVC, and its tensile property is also greatly improved, especially for outdoor rigid PVC plastic products. Compared with other impact modifiers, ACR has better processability, impact resistance, beautiful surface and excellent aging resistance.Our impact modifiers equivalent to the Dow Paraloid KM series,Kane Ace FM series,LG IM series,Mitsubishi Metablen W series,Arkema DURASTRENGTHD series,AKDENZ DMA,Shandong Rike HL series.The size of ACR particles is one of the key factors that affect the impact modification effect. The particle size of good ACR rubber core should be about 0.1-o.5, too large and too small is not good. In particular, it should be noted that under the same processing conditions, the impact strength of PVC / ACR blends prepared by different stable systems is quite different. If barium stearate cadmium stearate is used as stabilizer under the same conditions, it has higher impact resistance than lead salt stabilizer.Acrylic impact modifieris a copolymer of methyl methacrylate, acrylate and other monomers. ACR is the best impact modifier developed in recent years. It can increase the impact strength of the material by dozens of times. It is a shell composed of methyl methacrylate and ethyl acrylate polymer. The chain segments with butyl acrylate crosslinked rubber elastomer as the core are distributed in the inner layer of particles. It is especially suitable for the impact modification of PVC plastic products for outdoor use. Compared with other modifiers, ACR used as impact modifier in PVC plastic door and window profiles has the characteristics of good processing performance, smooth surface, good aging resistance and high fillet strengthLS51 equivalent to Dow KM-1,Kaneka FM-22,Arkema D-200,LG IM-808,Baerlocher E-ST 2D.LS50 equivalent to Dow KM-342,,Kaneka FM-50,Arkema D-529,LG IM-812,Baerlocher E-ST 4.LS55 equivalent to Dow KM-369 or KM390,,Kaneka FM-55,Arkema D-520.LS-61 equivalent to Dow KM-355P,,Kaneka FM-40,Arkema D-320,LG IM-809,Baerlocher E-ST 3For TDS and MSDS, you can contact our Sales and Marketing Department or you can reach us through thecontact page.FAQs of Acrylic Impact Modifier:

Q: What is the physical form and appearance of Acrylic Impact Modifier?

A: Acrylic Impact Modifier is available in powder form and appears as a clear powder.Q: What is the purity percentage of Acrylic Impact Modifier?

A: The purity of Acrylic Impact Modifier is 99.9%.Q: What industries is Acrylic Impact Modifier suitable for?

A: Acrylic Impact Modifier is suitable for industrial applications, including the textile industry.Q: What is the shelf life of Acrylic Impact Modifier?

A: The shelf life of Acrylic Impact Modifier is 2 years.Q: At what temperature should Acrylic Impact Modifier be stored?

A: Acrylic Impact Modifier should be stored at room temperature.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Oxidized Polyethylene Wax Category

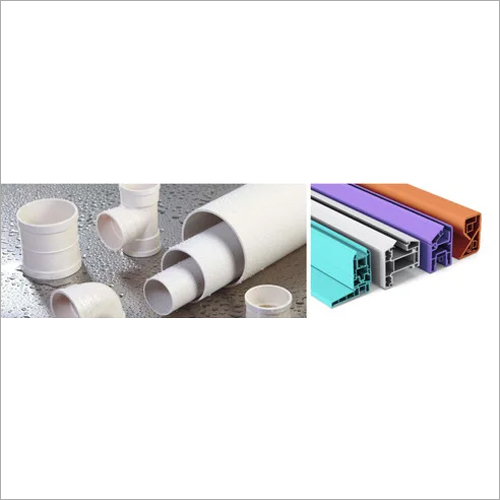

Chlorinated Polyethylene

Price Range 800.00 - 1350.00 USD ($) / Ton

Minimum Order Quantity : 1 Ton

Grade : Industrial Grade

Physical Form : Powder

Color : White

Storage : Stored in cool and draughty place

ACM Impact Modifier

Grade : Industrial Grade

Physical Form : Powder

Color : White

Storage : Other, Cool, dry place; sealed container

Chlorinated polyethylene

Price Range 1150.00 - 1350.00 USD ($) / Ton

Minimum Order Quantity : 5 Tons

Grade : Industrial Grade

Physical Form : Powder

Color : White

Storage : Room Temperature

CPE 135A

Price Range 945.00 - 1350.00 USD ($) / Ton

Minimum Order Quantity : 5 Tons

Grade : Industrial Grade

Physical Form : Powder

Color : White

Storage : Room Temperature

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese