- Home Page

- Company Profile

-

Our Products

- Oxidized Polyethylene Wax

- Pvc impact modifier

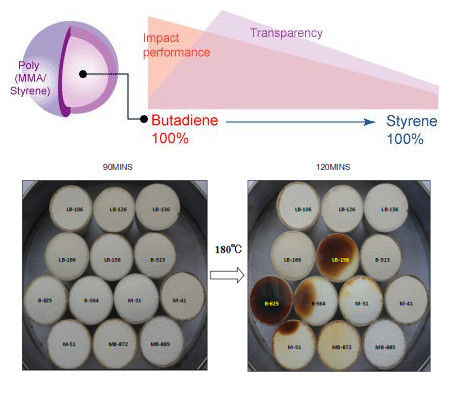

- MBS Impact Modifier

- pvc impact modifier

- PVC Impact Modifier

- Chlorinated Polyethylene

- Acrylic Impact Modifier

- ACM Impact Modifier

- CPE 135A

- ACM Impact Modifier

- Acrylic Impact Modifier

- MBS RESIN

- Acrylic Impact Modifier

- Chlorinated polyethylene

- ACM Impact Modifier

- PVC Impact Modifier

- OA- 123 Oxidized Polyethylene Wax

- Oxidized Polyethylene Wax module

- Oxidized polyethylene wax module

- Oxidized polyethylene wax module

- Lubricant Processing Aid

- MBS Impact Modifier

- PVC Foaming Regulator

- Acrylic Processing Aid

- Acrylic Processing Aid

- High molecular weight processing aid

- PVC Foaming Regulator

- PVC Processing Aid

- Processing Aid ACR401

- Lubricant Processing Aid

- San Processing Aid

- Pvc Processing Aid

- Impact Modifier for PVC Pipe

- High Molecular Weight Processing Aid

- PVC Lubricating Processing Aids

- Acrylic Processing Aids

- SAN Processing Aid

- Acrylic Processing Aid

- Processing Aid

- Lubricant Processing Aid

- Acrylic Impact Modifier AIM60

- Acrylic Impact Modifier AIM-60

- MBS IMPACT MODIFIER B-126

- Acrylic Processing Aid

- PVC External Lubricant

- PVC Internal Lubricant

- PVC Internal Lubricant

- PVC Lubricants

- External PVC lubricants

- Oxidized Polyethylene wax

- Lubricants for PVC

- PVC Internal Lubricant

- Lubricant for PVC

- PVC External Lubricant

- PVC Lubricants Flaxes

- Lubricant Processing Aid

- PVC LUBRICANT PROCESSING AID P-175

- Acrylic processing aid module

- Pvc Processing Aid Acr-401

- Hydrotalcite

- Calcium stearate

- ASA Resin

- Chlorinated Polyethylene

- PVC Raw Material

- NC Blowing Agent

- Additives for PVC

- MBS Impact Modifier

- Antioxidant SBM

- MBS Resin

- PVC Additives

- CPE 135B

- PVC Compound Stabilizer

- Calcium Stearate

- Additives for PVC

- Methyl tin stabilizer

- PVC Raw Material

- PVC Foaming Regulator

- ASA Granule

- PVC Stabilizer

- Dike tone

- Chlorinated Polyethylene

- AC Blowing Agent

- Hydrotalcite HTC-3

- Low Density Oxidized Polyethylene

- High Density Oxidized Polyethylene

- PVC Foaming Agent

- PVC Heat Stabilizer

- Synthetic Hydrotalcite

- Chlorinated Polyethylene

- CPVC 1

- ASA Resin

- Ca Zn Stabilizer

- PVC Additives

- Wax

- Oxidized Pe Wax

- Oxidized Polythethylene Wax (OPE)

- High Density Oxidized Polyethylene

- Oxidized PE Wax

- Oxidized Polyethylene Wax

- Oxidized Polyethylene Wax

- PE WAX

- Low Density Oxidized Polyethylene

- PE Wax

- Fischer Tropsch Wax

- FT Wax

- Polypropylene Wax

- Oxidized polyethylene wax module

- Oxidized polyethylene wax module

- Chlorinated Polyethylene CPE135A

- PVC Stabilizer

- PVC Impact Modifier Module

- Oxidized Polyethylene Wax

- More Info

- Contact Us

ACM Impact Modifier

ACM Impact Modifier Specification

- Shelf Life

- 24 months

- Shape

- Granular/Powder

- Boiling point

- Not applicable (polymer does not boil)

- Grade

- Industrial Grade

- Other Names

- ACM

- Ph Level

- Neutral (7-8)

- Solubility

- Insoluble in water

- Smell

- Odorless

- Structural Formula

- Acrylic Copolymer

- Melting Point

- >150C

- Poisonous

- No

- Molecular Formula

- (C10H10)n (typical acrylic copolymer unit)

- Application

- Used as impact modifier for PVC, pipes, sheets, profiles

- Physical Form

- Powder

- Density

- 0.55 Gram per cubic centimeter(g/cm3)

- Molecular Weight

- Variable (polymer)

- Taste

- Odorless

- Particle Size

- 40-80 mesh

- Chemical Name

- Acrylic Copolymer Impact Modifier

- CAS No

- 92160-69-1

- Type

- Impact Modifier

- Color

- White

- EINECS No

- No Data

- Usage

- PVC modification, Plastic additives

- Purity(%)

- 99

- Storage

- Cool, dry place; sealed container

- Appearance

- White powder

- Compatible Polymers

- PVC, CPVC

- Weatherability

- Good

- Glass Transition Temperature

- 45C

- Thermal Stability

- Excellent under normal processing temperature

- Bulk Density

- 0.40-0.55 g/cm

- Refractive Index

- 1.48 approx.

- Packing

- 25 kg/bag

- Moisture Content

- 0.3%

- Processing Temperature

- 160C to 200C (recommended for PVC extrusion)

- Regulatory Status

- Complies with general industrial standards

- Additive Content

- Optimized for impact resistance

About ACM Impact Modifier

Physicochemical Properties

| Index/Product Name | ACM Series |

| Physical Form | White free flowing powder |

| Particle size 40 mesh (%) | 98 |

| Percent volatiles(%) | 1.0 |

| Bulk Density (g/cc) | 0.45-0.55 |

Outstanding Impact Resistance for PVC Applications

ACM Impact Modifier is specifically engineered to elevate the toughness of rigid PVC and CPVC components. Its optimized additive content and granular consistency enable uniform dispersion during processing, leading to durable and long-lasting finished products. Ideal for piping, profile, and sheet extrusion, it ensures reliable physical properties and resistance to external impacts.

Reliable Thermal Stability & Processing Efficiency

With excellent thermal stability, ACM Impact Modifier performs efficiently within the recommended processing range of 160C to 200C. This compatibility minimizes the risk of polymer degradation, facilitating smooth manufacturing and consistent output quality. Its application accelerates production while maintaining high-performance standards.

FAQs of ACM Impact Modifier:

Q: How should ACM Impact Modifier be processed in PVC extrusion applications?

A: ACM Impact Modifier is recommended for processing at temperatures between 160C and 200C. It should be evenly blended with PVC or CPVC resins to ensure uniform impact enhancement. Proper dispersion ensures optimal physical properties in extruded products.Q: What benefits does ACM Impact Modifier provide to PVC products?

A: This impact modifier significantly increases the toughness, durability, and weatherability of PVC and CPVC products. It helps finished materials withstand physical impacts and environmental stress, resulting in high-performance pipes, sheets, and profiles.Q: When is the ACM Impact Modifier added during PVC manufacturing?

A: ACM Impact Modifier is incorporated during the compounding stage, before extrusion or molding. It blends with the base polymer and other additives in the formulation to deliver optimal mechanical properties.Q: Where should ACM Impact Modifier be stored for maintaining quality?

A: Store ACM Impact Modifier in sealed containers, placed in a cool, dry area away from moisture and direct sunlight. Proper storage preserves its shelf life and ensures consistent quality during usage.Q: What types of polymers is ACM Impact Modifier compatible with?

A: The product is mainly designed for use with PVC and CPVC polymers. Its chemical structure ensures compatibility and effective performance enhancement in these materials.Q: What is the recommended packing and shelf life for ACM Impact Modifier?

A: ACM Impact Modifier is supplied in 25 kg bags and has a shelf life of 24 months when properly stored under suitable conditions.Q: How does ACM Impact Modifier comply with regulatory standards?

A: It meets general industrial standards and is safe for use in PVC modification processes. The product is non-poisonous, odorless, and exhibits neutral pH, making it suitable for a wide range of plastic additive applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Oxidized Polyethylene Wax Category

Chlorinated Polyethylene

Price Range 800.00 - 1350.00 USD ($) / Ton

Minimum Order Quantity : 1 Ton

Grade : Industrial Grade

Type : Chemical Additive

Storage : Stored in cool and draughty place

Smell : Stimulus

Acrylic Impact Modifier

Price Range 1150.00 - 1380.00 USD ($) / Ton

Minimum Order Quantity : 5 Tons

Grade : Industrial Grade

Type : Impact modifier, Other

Storage : Room Temperature

Smell : Stimulus

MBS RESIN

Grade : Industrial Grade

Type : Other, Polymer Additive

Storage : Other, Cool and Dry Place

Smell : Other, Neutral

Acrylic Impact Modifier

Price Range 350.00 - 1250.00 USD ($) / Ton

Minimum Order Quantity : 5 Tons

Grade : Industrial Grade

Type : Chemical Additive Agent

Storage : Room Temperature

Smell : Stimulus

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese