- Home Page

- Company Profile

-

Our Products

- Oxidized Polyethylene Wax

- Pvc impact modifier

- MBS Impact Modifier

- pvc impact modifier

- PVC Impact Modifier

- Chlorinated Polyethylene

- Acrylic Impact Modifier

- ACM Impact Modifier

- CPE 135A

- ACM Impact Modifier

- Acrylic Impact Modifier

- MBS RESIN

- Acrylic Impact Modifier

- Chlorinated polyethylene

- ACM Impact Modifier

- PVC Impact Modifier

- OA- 123 Oxidized Polyethylene Wax

- Oxidized Polyethylene Wax module

- Oxidized polyethylene wax module

- Oxidized polyethylene wax module

- Lubricant Processing Aid

- MBS Impact Modifier

- PVC Foaming Regulator

- Acrylic Processing Aid

- Acrylic Processing Aid

- High molecular weight processing aid

- PVC Foaming Regulator

- PVC Processing Aid

- Processing Aid ACR401

- Lubricant Processing Aid

- San Processing Aid

- Pvc Processing Aid

- Impact Modifier for PVC Pipe

- High Molecular Weight Processing Aid

- PVC Lubricating Processing Aids

- Acrylic Processing Aids

- SAN Processing Aid

- Acrylic Processing Aid

- Processing Aid

- Lubricant Processing Aid

- Acrylic Impact Modifier AIM60

- Acrylic Impact Modifier AIM-60

- MBS IMPACT MODIFIER B-126

- Acrylic Processing Aid

- PVC External Lubricant

- PVC Internal Lubricant

- PVC Internal Lubricant

- PVC Lubricants

- External PVC lubricants

- Oxidized Polyethylene wax

- Lubricants for PVC

- PVC Internal Lubricant

- Lubricant for PVC

- PVC External Lubricant

- PVC Lubricants Flaxes

- Lubricant Processing Aid

- PVC LUBRICANT PROCESSING AID P-175

- Acrylic processing aid module

- Pvc Processing Aid Acr-401

- Hydrotalcite

- Calcium stearate

- ASA Resin

- Chlorinated Polyethylene

- PVC Raw Material

- NC Blowing Agent

- Additives for PVC

- MBS Impact Modifier

- Antioxidant SBM

- MBS Resin

- PVC Additives

- CPE 135B

- PVC Compound Stabilizer

- Calcium Stearate

- Additives for PVC

- Methyl tin stabilizer

- PVC Raw Material

- PVC Foaming Regulator

- ASA Granule

- PVC Stabilizer

- Dike tone

- Chlorinated Polyethylene

- AC Blowing Agent

- Hydrotalcite HTC-3

- Low Density Oxidized Polyethylene

- High Density Oxidized Polyethylene

- PVC Foaming Agent

- PVC Heat Stabilizer

- Synthetic Hydrotalcite

- Chlorinated Polyethylene

- CPVC 1

- ASA Resin

- Ca Zn Stabilizer

- PVC Additives

- Wax

- Oxidized Pe Wax

- Oxidized Polythethylene Wax (OPE)

- High Density Oxidized Polyethylene

- Oxidized PE Wax

- Oxidized Polyethylene Wax

- Oxidized Polyethylene Wax

- PE WAX

- Low Density Oxidized Polyethylene

- PE Wax

- Fischer Tropsch Wax

- FT Wax

- Polypropylene Wax

- Oxidized polyethylene wax module

- Oxidized polyethylene wax module

- Chlorinated Polyethylene CPE135A

- PVC Stabilizer

- PVC Impact Modifier Module

- Oxidized Polyethylene Wax

- More Info

- Contact Us

PVC Lubricating Processing Aids

MOQ : 10 Tons

PVC Lubricating Processing Aids Specification

- Application

- Industrial, Plastic

- Shape

- Granules

- Shelf Life

- 2 Years

- Physical Form

- Powder

- Smell

- Stimulus

- Grade

- Industrial Grade

- Type

- Chemical Additive

- Color

- White powder

- Purity(%)

- 99.9%

- Storage

- Room Temperature

- Appearance

- Clear Powder

PVC Lubricating Processing Aids Trade Information

- Minimum Order Quantity

- 10 Tons

- FOB Port

- Shandong, China

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Cash Advance (CA)

- Supply Ability

- 10000 Tons Per Month

- Delivery Time

- 7-12 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- white plastic bags snake skin bags kraft bags 25kg per bag or 20kg per bag 13tons in a 20GP container(without pallets) 8.8tons in a 20GP container(with pallets) 19.8tons in a 40GP container(with pallets) 26tons in a 40GP container(without pallets) 8tons in a 20GP container(with pallets and 500kg per bag).

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Central America, South America, Western Europe, Asia, Africa

- Main Domestic Market

- All India

About PVC Lubricating Processing Aids

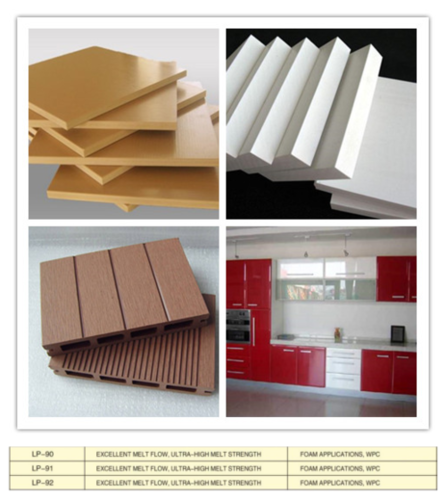

Offered LP series lubricating processing aids are acknowledged for their advanced formulation. These are used for producing different types of PVC items like pipes, foam sheet, film, profiles, pipes and bottles to name a few. Its low amount application during molding and processing of PVC helps to optimize fluidity and metal releasing attributes of produced items. Inclusion of these lubricating processing aids enhances surface brightness of produced PVC items, prolongs their durability and ensures higher production. Although, these lubricating products can be used independently, still these are along with other processing materials to enhance fusion properties of PVC resin.Acrylic Processing Aid LP -21,B-23Known for its high and medium molecular weight, LP-21,B-23 is used as one of the common raw materials during processing of PVC products. Its acrylic copolymer content optimizes processing attributes of PVC. Moreover, minimal addition of this low cost product provides outstanding processing result.Its addition not only improves melting strength, but also ensures uniformity of melting of all the compounds. Most importantly, LP-21,B-23 accelerates rapid fusion and contributes to flexibility of processed items. This acrylic processing aid enhances surface attributes of PVC items, maintains homogeneity of wall thickness and optimizes thermoforming properties.Acrylic Processing Aid LS-530,LP-40 LS-530,LP-40 is used during processing of PVC items to optimize their rigidity level. Known for its polymethacrylate resin based content, this high molecular weight processing aid not only improves standard of PVC processing, but also optimizes different properties of produced items.Inclusion of LS-530,LP-40 in processing quickens solidification of PVC by promoting freezing, enhances viscous properties and elasticity level, improves thermal performance and internal strength of PVC. It is used as an indispensable part of PVC foam processing step as it helps to maintain original quality of microcells produced by blowing agents. Presence of these microcells ensures less density and better strength of foam. Moreover, this processing aid improves surface properties of PVC items.What is more, inclusion of this processing aid promotes better dispersibility of additives used during PVC production. Higher scattering of additives promotes uniformity of melting of PVC. This processing aid is perfect for making weather proof PVC items used in construction arena. Ultra-High Molecular Weight Processing Aids SeriesAcrylic processing aid LP-50,LP-80,LP-81 is mainly used for production of standard grade durable PVC products and foam. Rapid fusion properties, less torque, standard expansion and better melting strength are some of the key advantages of using this processing aid.LP-50,LP-80,LP-81 promotes better processing graph ( based on different parameters) and ensures higher impact strength by promoting quick control of fusion during production of durable PVC items. Excellent melting performance, flexibility of melting and better sizing are some of the main benefits of using this processing aid.Offered processing aid is reckoned for its exceptional foaming properties that are required for producing PVC foam profiles and foam core pipes. Its minimal addition provides unique result. Typical Physical Properties: Index/Product Name LS-01 LS-02 LS-400 LS-901 Appearance White fluid powder Granularity(throughput efficiency of 40 mesh)(%) 98 % Volatile component (%) 1.0% 1.5% Intrinsic viscosity ()25oC 3.0-4.0 2.0-3.0 10-13 10-13 Density(g/cm^3) 0.3-0.5 Purpose and Dosage: Item LS-01 LS-02 LS-400 LS-901 Application Pipes Pipe fitting Profiles,sheets Pipes Profiles Foam pipes Foam sheets Foam pipes Foam sheets Recommended dosage (phr) 0.5-2 2-3 1.5-2.5 1-2 1.5-3 0 0 5-8 7-10 Properties High output,high gloss Good fusion fluidity Even bubbles,low density Fast fusionFAQs of PVC Lubricating Processing Aids:

Q: What is the physical form and appearance of PVC Lubricating Processing Aids?

A: PVC Lubricating Processing Aids are available in a clear powder form with a granule shape.Q: What is the purity percentage of PVC Lubricating Processing Aids?

A: The purity of PVC Lubricating Processing Aids is 99.9%.Q: How long is the shelf life of PVC Lubricating Processing Aids?

A: The shelf life of PVC Lubricating Processing Aids is 2 years.Q: What type of applications are PVC Lubricating Processing Aids suitable for?

A: PVC Lubricating Processing Aids are suitable for industrial and plastic applications.Q: Under what storage conditions should PVC Lubricating Processing Aids be kept?

A: PVC Lubricating Processing Aids should be stored at room temperature.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in MBS Impact Modifier Category

Impact Modifier for PVC Pipe

Price Range 350.00 - 1100.00 USD ($) / Ton

Minimum Order Quantity : 5 Tons

Application : Plastic

Shape : Granules

Type : Chemical Additive

Shelf Life : 1 Years

PVC Foaming Regulator

Price Range 1700.00 - 1850.00 USD ($) / Ton

Minimum Order Quantity : 5 Tons

Application : Industrial

Shape : Granules

Type : Other, PVC satbilizers, lead stabilizer

Shelf Life : 1 Years

PVC Foaming Regulator

Price Range 850.00 - 1250.00 USD ($) / Ton

Minimum Order Quantity : 5 Tons

Application : Industrial, Plastic

Shape : Granules

Type : Chemical Additive

Shelf Life : 1 Years

Lubricant Processing Aid

Price Range 1150.00 - 1650.00 USD ($) / Ton

Minimum Order Quantity : 10 Tons

Application : Industrial, Plastic

Shape : Granules

Type : Other

Shelf Life : 2 Years

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese