- Home Page

- Company Profile

-

Our Products

- Oxidized Polyethylene Wax

- Pvc impact modifier

- MBS Impact Modifier

- pvc impact modifier

- PVC Impact Modifier

- Chlorinated Polyethylene

- Acrylic Impact Modifier

- ACM Impact Modifier

- CPE 135A

- ACM Impact Modifier

- Acrylic Impact Modifier

- MBS RESIN

- Acrylic Impact Modifier

- Chlorinated polyethylene

- ACM Impact Modifier

- PVC Impact Modifier

- OA- 123 Oxidized Polyethylene Wax

- Oxidized Polyethylene Wax module

- Oxidized polyethylene wax module

- Oxidized polyethylene wax module

- MBS Impact Modifier

- PVC Foaming Regulator

- Acrylic Processing Aid

- Acrylic Processing Aid

- High molecular weight processing aid

- PVC Foaming Regulator

- PVC Processing Aid

- Processing Aid ACR401

- Lubricant Processing Aid

- San Processing Aid

- Pvc Processing Aid

- Impact Modifier for PVC Pipe

- High Molecular Weight Processing Aid

- PVC Lubricating Processing Aids

- Acrylic Processing Aids

- SAN Processing Aid

- Acrylic Processing Aid

- Processing Aid

- Lubricant Processing Aid

- Acrylic Processing Aid

- Hydrotalcite

- ASA Resin

- Calcium stearate

- Chlorinated Polyethylene

- PVC Raw Material

- Additives for PVC

- NC Blowing Agent

- Antioxidant SBM

- MBS Resin

- MBS Impact Modifier

- PVC Additives

- CPE 135B

- Calcium Stearate

- PVC Compound Stabilizer

- Methyl tin stabilizer

- Additives for PVC

- PVC Raw Material

- ASA Granule

- PVC Stabilizer

- PVC Foaming Regulator

- Chlorinated Polyethylene

- Dike tone

- AC Blowing Agent

- Hydrotalcite HTC-3

- Low Density Oxidized Polyethylene

- High Density Oxidized Polyethylene

- PVC Foaming Agent

- PVC Heat Stabilizer

- Synthetic Hydrotalcite

- Chlorinated Polyethylene

- CPVC 1

- ASA Resin

- Ca Zn Stabilizer

- PVC Additives

- Wax

- Oxidized Pe Wax

- Oxidized Polythethylene Wax (OPE)

- High Density Oxidized Polyethylene

- Oxidized PE Wax

- Oxidized Polyethylene Wax

- Oxidized Polyethylene Wax

- PE WAX

- Low Density Oxidized Polyethylene

- PE Wax

- Fischer Tropsch Wax

- FT Wax

- Polypropylene Wax

- Oxidized polyethylene wax module

- Oxidized polyethylene wax module

- Chlorinated Polyethylene CPE135A

- PVC Stabilizer

- Oxidized Polyethylene Wax

- More Info

- Contact Us

Acrylic Processing Aids

Acrylic Processing Aids Specification

- Physical Form

- Powder

- Application

- Industrial, Plastic

- Particle Size

- 98%

- Grade

- Industrial Grade

- Shelf Life

- 2 Years

- CAS No

- 25852-37-3

- Type

- Chemical Additive

- Usage

- Plastic Auxiliary Agents

- Purity(%)

- 99.9%

- Appearance

- Other

Acrylic Processing Aids Trade Information

- Minimum Order Quantity

- 10 Tons

- FOB Port

- Shandong Sheng, China

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Cash Advance (CA)

- Supply Ability

- 10000 Tons Per Month

- Delivery Time

- 7-12 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- LP-90 can be packed in 25kg woven bag and 500kg bulk bag

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- COA,MSDS,TDS,SGS etc.

About Acrylic Processing Aids

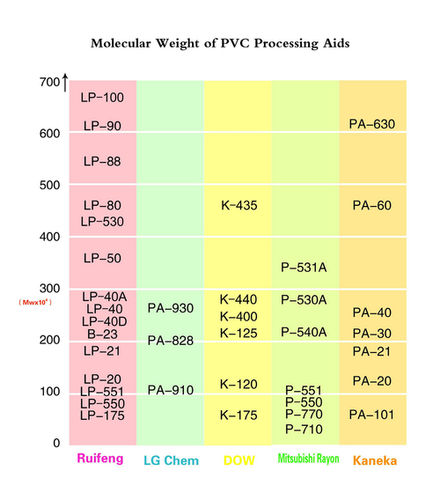

Product Description LP-90 is a latest acrylic processing aid with ultra high molecular weight, which is used mainly for foam and PVC applications. The performance properties of this acrylic processing aid are: Low torqueFaster fusionHigh melt strengthExpansion Physicochemical Properties This is a white free-flowing powder with 0.40-0.55g/cm3 as bulk density. It is not dissolvable in water, and dissolvable in chloroform. Index/Product Name LP-90 Appearance White free-flowing powder Particle size 40 mesh(%) 98 volatiles(%) 1.5 Viscosity () (Ubbelohde Viscometer) 10.5-13.0 Product Benefits and Applications Processing window is improved and impact is enhanced by LP-90 through quick fusion control for many PVC applications. Using LP-90, one can improve melt elasticity, melt strength and sizing. The high foaming efficiency of the LP-90 allows converters to meet the demanding requirements in formulations of foam profile and foam core pipes, making use of lower addition levels. The applications of LP-90 in rigid PVC, include pipes, fittings, roofing sheets, window profiles, siding, fences, foamed products, injection-molded parts, wood-plastic composites, etc. Material Safety Data Sheets MSDS outlines hazards as well as safe handling methods. Customers can consult the company for MSDS of LP-90 before handling for extra information relating to personal protective equipment, safety, health and environmental. Storage, Packing & Transportation LP-90 can be packed in 25kg woven bag and 500kg bulk bag. One must avoid isolation, and drench; and store the product in cool and draughty place. Its shelf life is one year. Countertypes PA-630 K-435 Technical Specifications Item LP-21 B-23 Appearance White free flowing powder viscosity()(Ubbelohde Viscometer) 4.5-5.0 4.8-5.3 Volatilization Content(%) 1.5% Granularity (40 mesh passing percentage> (%) 98 PRODUCTS GRADES ROHM & HAAS KANEKA ARKEMA LG CHEM BAERLOCHER ACRYLIC PROCESSING AIDS LP-551 P-550/P-551 PA-821 LP-20 K-120ND PA-20/PA-210 PA-910 3FK B-23/LP-21 K-125 PA-21/PA-310 PA-828 10F NM-530 PA-40/LS-530 K-400 PA-40 P-530 PA-930 20F LP-50 K-440 LP-80 PA-60/PA-610 LP-81 LP-82 LP-90 K-435 PA-630FAQs of Acrylic Processing Aids:

Q: What is the physical form of Acrylic Processing Aids?

A: Acrylic Processing Aids are available in powder form.Q: What is the grade classification of this product?

A: This product is classified as Industrial Grade.Q: What is the purity of Acrylic Processing Aids?

A: The purity of Acrylic Processing Aids is 99.9%.Q: What are the typical applications of Acrylic Processing Aids?

A: Acrylic Processing Aids are used for PVC applications, including pipes, fittings, roofing sheets, window profiles, siding, fences, foamed products, injection-molded parts, and wood-plastic composites.Q: What is the shelf life of this product?

A: The shelf life of Acrylic Processing Aids is 2 years.Q: What is the particle size distribution?

A: The particle size of Acrylic Processing Aids is 98%.Q: What is the density range of Acrylic Processing Aids?

A: The density range of Acrylic Processing Aids is 0.40-0.55g per cubic meter (g/m).

- Minimum Order Quantity

- 10 Tons

- Supply Ability

- 10000 Tons Per Month

- Delivery Time

- 7-12 Days

- Main Domestic Market

- All India

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Asia, Africa

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in MBS Impact Modifier Category

PVC Foaming Regulator

Price Range 1700.00 - 1850.00 USD ($) / Ton

Minimum Order Quantity : 5 Tons

Appearance : White flowing powder

Application : Industrial

Storage : Room Temperature

Shelf Life : 1 Years

PVC Lubricating Processing Aids

Price Range 850.00 - 1250.00 USD ($) / Ton

Minimum Order Quantity : 10 Tons

Appearance : Clear Powder

Application : Industrial, Plastic

Storage : Room Temperature

Shelf Life : 2 Years

Pvc Processing Aid

Price Range 1250.00 - 1350.00 USD ($) / Ton

Minimum Order Quantity : 5 Tons

Appearance : Yellowish Powder

Application : Plastic, Textile Industry

Storage : Room Temperature

Shelf Life : 1 Years

High molecular weight processing aid

Price Range 1280.00 - 1550.00 USD ($) / Ton

Minimum Order Quantity : 5 Tons

Appearance : Clear Powder

Application : Industrial, Plastic, Textile Industry

Storage : Room Temperature

Shelf Life : 2 Years

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese